what are the three basic areas of a machine that require safeguarding

A full facility review often performed by a third party the machine guarding survey typically takes a day or two on-site. Sensing devices Sensor technology can certainly improve the safety standards.

Osha Safe Guarding Poster Compliance Poster Company

The type of operation the size or shape of stock the method of handling the physical layout of the work area the type of.

. First theres the point of operation which is. The point of operation. The type of operation size or shape of stock method of handling the physical layout of the work area.

What are the three basic areas of a machine that require. There are many ways to safeguard machinery. Dangerous moving parts require safeguarding because these three areas of the machine are most likely to cause injuries.

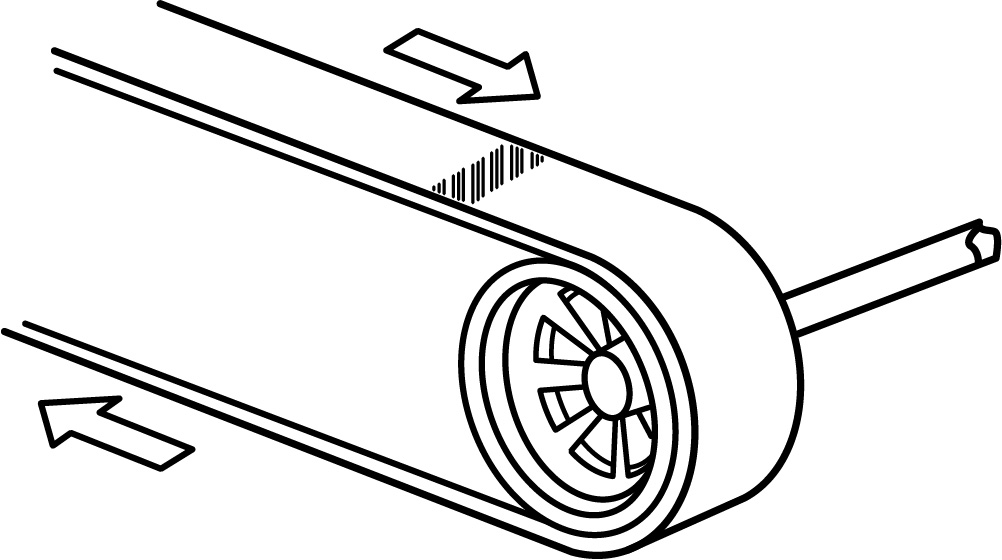

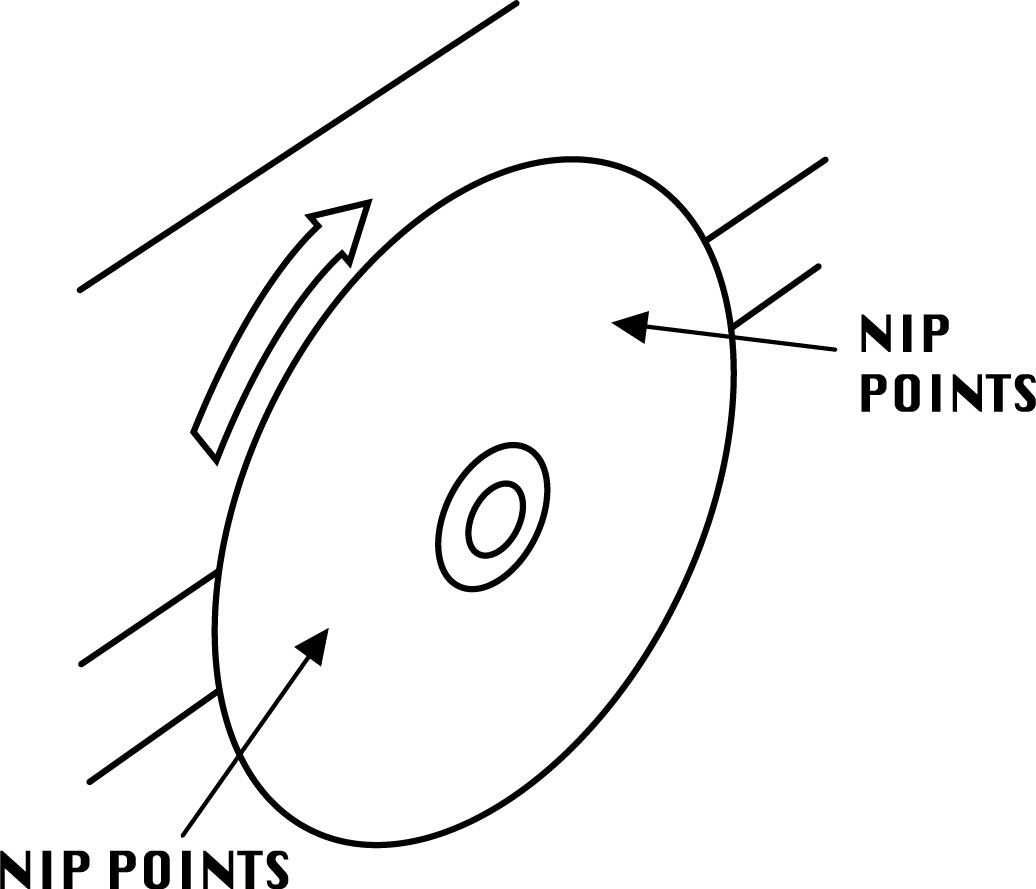

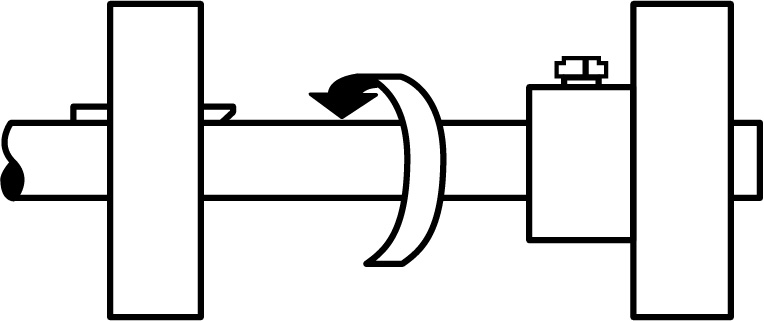

The point of operation That point where work is performed on the. Power Transmission Apparatus This includes the areas of the machine that are transmitting power for the machine to work. Dangerous moving parts in three basic areas require safeguarding.

Each piece of machinery has its own unique mechanical and non-mechanical hazards. All machines consist of three fundamental areas. Trip rods two-hand controls and pressure-sensitive body bars are some of the examples of safety control devices.

Generally speaking every type of industrial machinery can be broken down into three basic elements each of which may include many parts. OSHA states that mechanical hazards are most likely to occur in three major areas. There are many ways to design and use machine safeguarding.

The moving parts on a machine do not constitute a potential machine guarding hazard. The point of operation the power transmission device and the operating controls. That point where work is performed on the material such as cutting shaping boring or forming of.

That point where work is performed on the material such as cutting shaping boring or forming of. Some of the machines which usually require point of operation guarding are guillotine cutters shears alligator shears power presses milling machines power saws jointers portable power. Machine safeguarding must be supplemented by an effective energy control lockouttagout program that ensures that employees are protected from hazardous energy sources during.

All machines consist of three fundamental areas. Machines can cause a variety of injuries ranging from minor abrasions burns or cuts. All machines consist of three fundamental areas.

The point of operation from where all the work is performed. Moving machine parts have the potential to cause severe workplace injuries such as crushed fingers or hands amputations burns or blindness. This could include chains pulleys gears and cranks.

Dangerous moving parts in three basic areas require safeguarding. The point of operation the power transmission device and the. Depending upon the dangerous part its Size position speed etc a guard should be selected generally the parts to be guarded fall within three categories.

The Machine Guarding Survey. Despite all machines having the same basic components. The point of operation.

The point of operation. Safeguards are essential for protecting. Prevent human access during hazardous machine motion.

The point of operation is the point where work is performed on the material such as.

Osha Requirements Machine Guarding Grainger Knowhow

Slide 1 Of 185 Objectives Objectives Course No 204 Machinery And Machine Guarding Standards Course Identify Basic Machinery Terms Identify Common Machines Ppt Download

Finding The Right Machine Safety Partner For Your Company Occupational Health Safety

Machine Guards Eliminate Hazards For Employees Article The United States Army

Welcome Crushed Hands And Arms Severed Fingers Blindness The List Of Possible Machinery Related Injuries Is As Long As It Is Horrifying There Seem Ppt Download

Chapter 1 Basics Of Machine Safeguarding

Osha Requirements Machine Guarding Grainger Knowhow

Osha Requirements Machine Guarding Grainger Knowhow

Osha Requirements Machine Guarding Grainger Knowhow

Six Types Of Machine Safeguard Devices

Chapter 1 Basics Of Machine Safeguarding